• Pre-feasibility and feasibility investigations

• Scheme optimization considering initial capital and long term operating and maintenance costs

• Conceptual planning and design including route and material selection

• Coordination of support services like topographical surveys, geotechnical investigations, way leave applications and environmental and social surveys on a managed service or turn key basis

• Detail design, including the following:

- Functional design specifications to establish sound operating philosophies

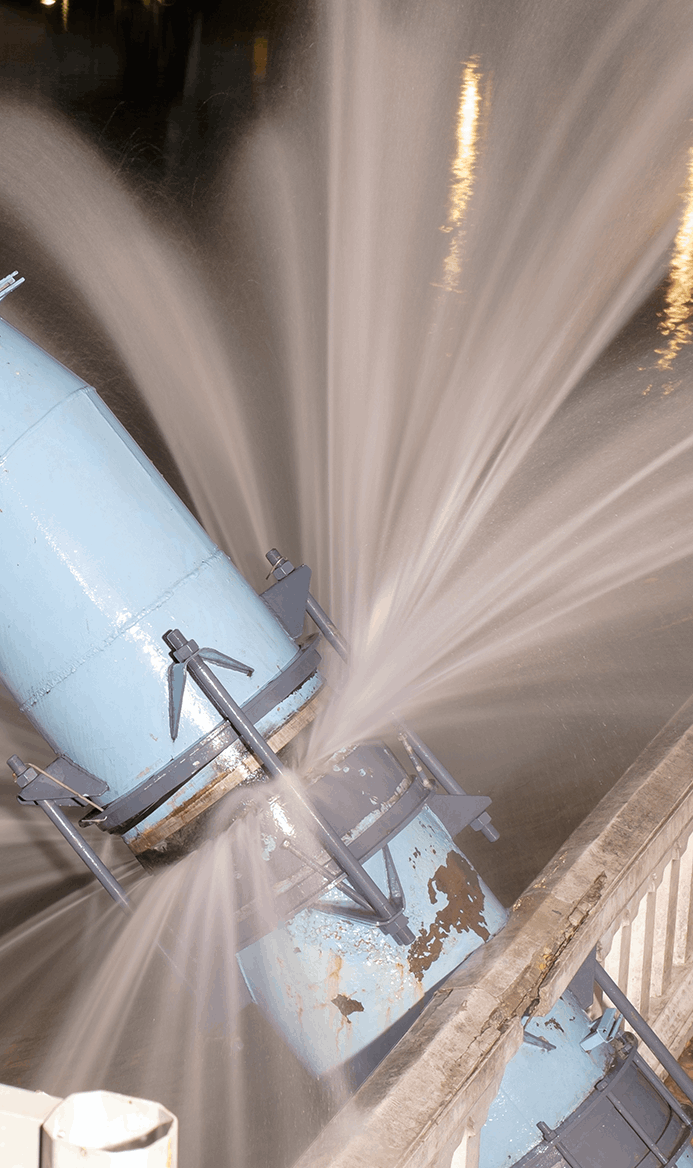

- Hydraulic and surge analysis

- Structural design and optimization of large diameter pipelines

- Valve selection, sizing and layout design

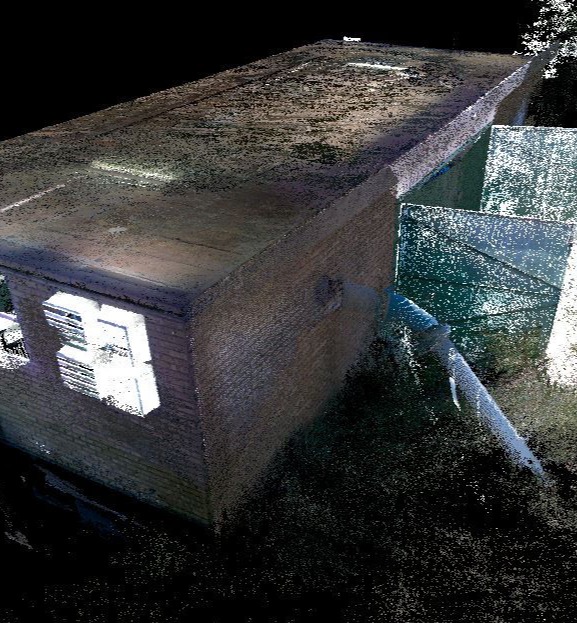

- Production of layout drawings and 3D geospatial design integration

- Production of longitudinal section drawings

- 3D CAD Design and detailing of chambers and appurtenances

- Production of standard and special details

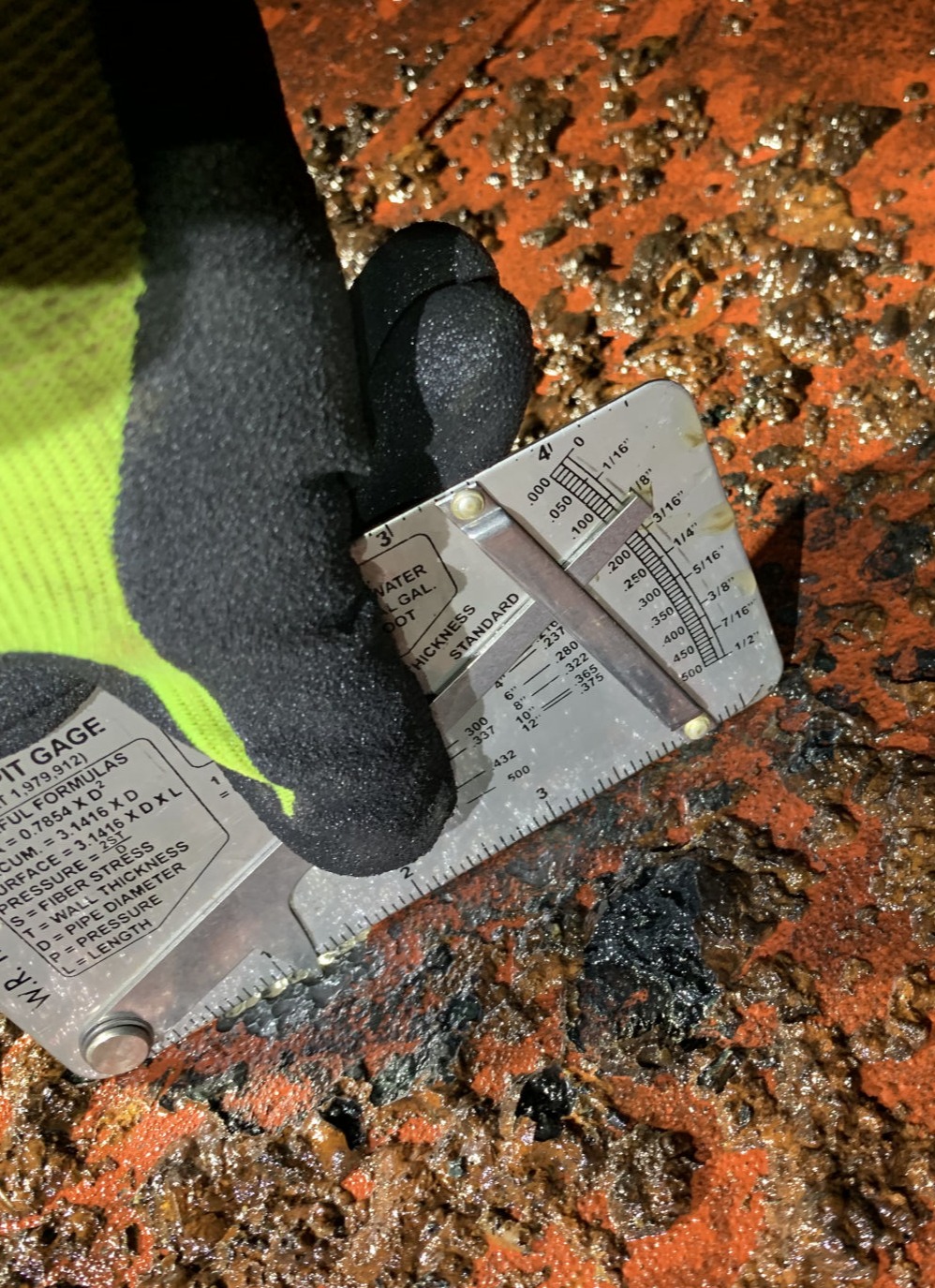

• Pipeline installation inspection, construction monitoring and commissioning

• Development of pipeline operation and maintenance manuals

• Development of project specifications, bills of quantities and data sheets for inclusion in contract documentation